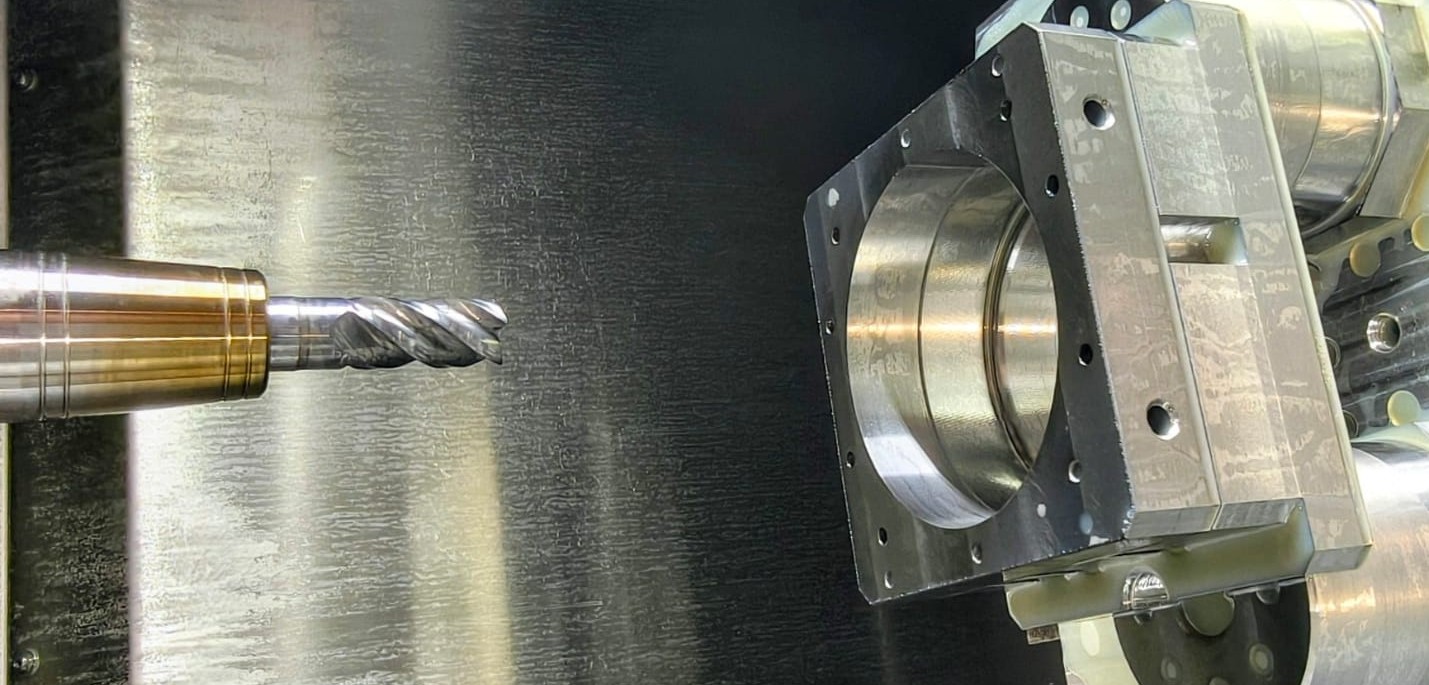

CNC Milling

Optimized toolpaths for tight-tolerance parts in light alloys and steels. We combine 5-axis machining with custom fixturing to reduce handling and guarantee repeatability.

- CAM programming validated with in-machine probing routines and spindle load tracking.

- Dedicated fixture design, including hydraulic and vacuum systems for complex geometries.