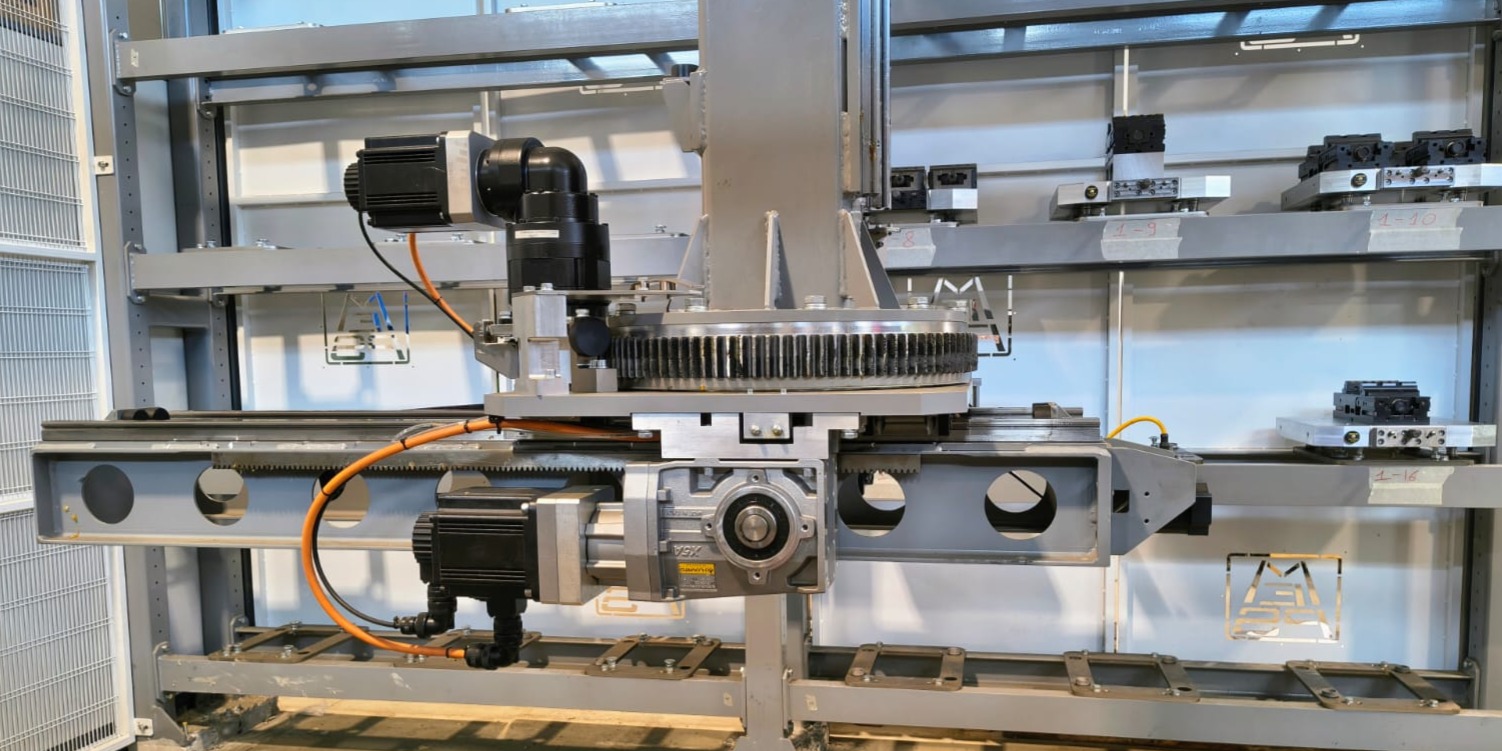

Robot-Fed Machining Cell

Integrated pallet system and Cartesian robot feeding two 5-axis machining centers, securing balanced spindle uptime and unattended shifts.

- Cartesian robot coordinates pallet queues with automatic fixture recognition.

- Dedicated fixtures include RFID tagging for program selection and traceability.

- Closed-loop measurement offsets maintain tolerances without halting production.